V

I

V

A

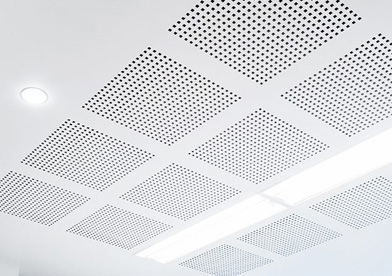

Gypsum Plastering Companies and Powder Suppliers in Kerala.

Welcome to Kerala, the home of top-notch Gypsum Plastering Companies. For years, Kerala has been known for its high-quality and reliable Gypsum Plastering Companies, which serve a variety of needs from residential homes to large commercial buildings. As a result, there are several Gypsum Plastering Companies in Kerala, among them we have earned an outstanding reputation for our products and services. Viva Gypsum is one of the leading Gypsum Powder supplies in India. We provide the best quality and most reliable gypsum powder for a long time. We are proud to present ourselves as one of the most reputed and experienced Gypsum Powder Suppliers in Kerala.

imported from iran

TECHNICAL REPORT

| S. No. | Particulars | Parameters | Unit | Test Result |

|---|---|---|---|---|

| 1 | Initial Setting Time | 5-9 | Minutes | 6-8 |

| 2 | Final Setting Time | 12-16 | Minutes | 16-18 |

| 3 | Colour | White | Brightness | 98.5% |

| 4 | Dry Bulk Density | 770kg /m3. Max | KG / m3 | 685-710 |

| 5 | Compressive Strength | 15-17 | N/mm2 | 15.5 |

| 6 | Fineness | 200 Mesh Pass 96% | % | 99% (Percent) |

| 7 | Sulphur Anhydride So3 | Not Less Than 35% | % | 51.41% |

| 8 | Calcium Oxide Ca0 | Not Less Than 2/3 of So3 | % | 37.17% |

| 9 | Approximate Coverage per bag on 12mm Thickness | Square Feet | 18-20 Square Feet |